Research & development is an integral part of any engineering parts manufacturing company and more so companies engaged in manufacturing of parts made out of polymer materials. With development of in new age materials and challenging environments in which machineries are used, ROYAL has dedicated team which works with Industrial users and manufacturers for continuous Research and development.

Our Research Team works very closely with our Customers to develop and validate material and compounds as per Application requirements.

For Extreme low temp. application NBR compounds

For Extreme High temp. application with good oil resistance Polyurethane

For Applications involving exposure to Moisture and water

For Application where Wiper subjected to hard contaminants and Cement particles

For Reverse engineering and identification of material as per Sample received from customer

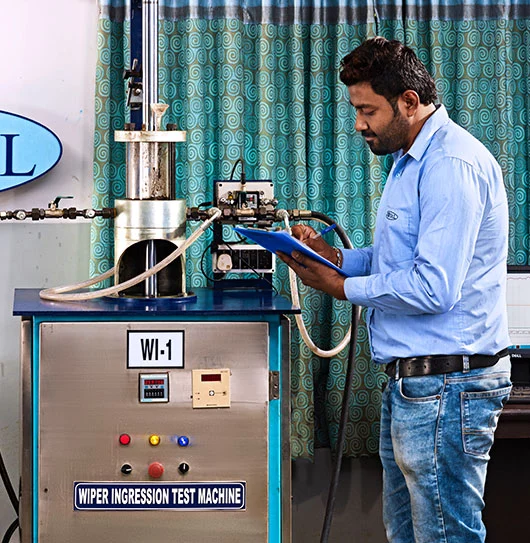

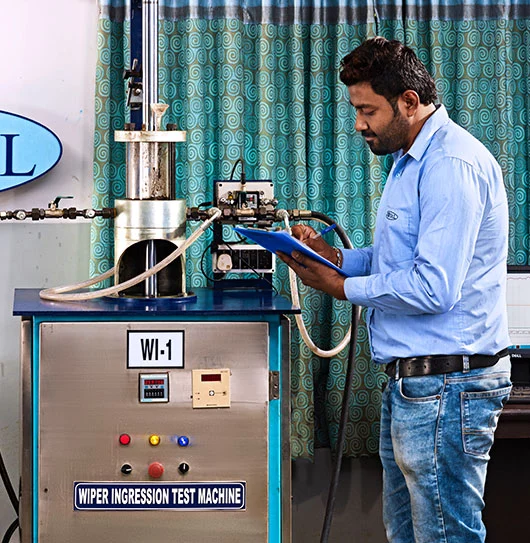

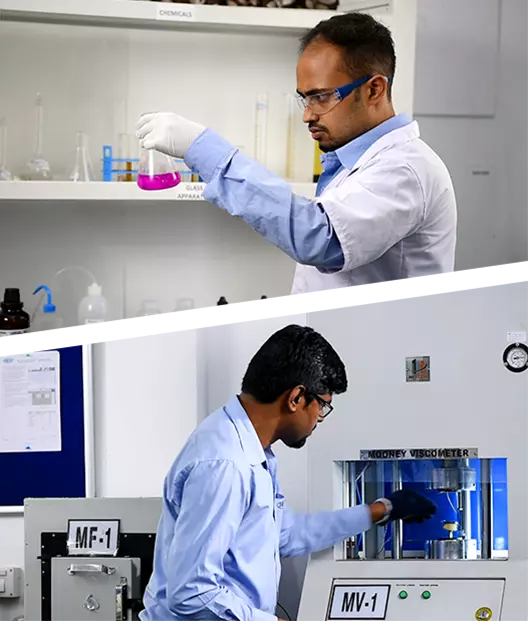

Royal has a fully equipped Laborarory to test all the incoming raw materials as well test newly developed material at lab scale for its intrinsic properties. All raw materials go through stringent quality checks before being put into manufacturing.

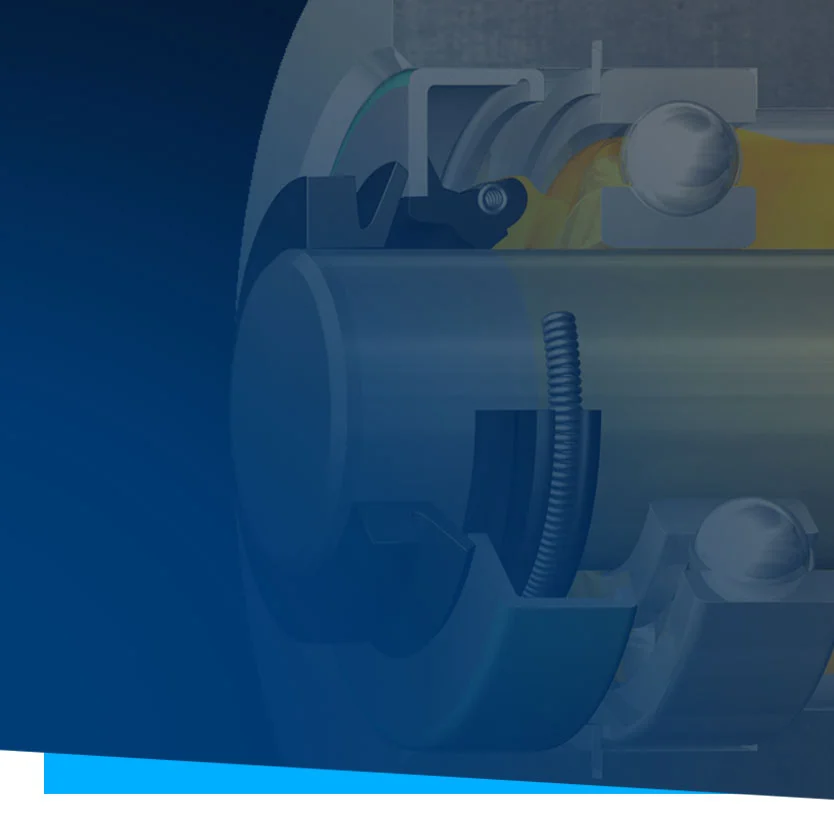

Royal has fully equipped hydraulic testing and validation facilities where we continuously test new designs of seals as well as conduct test for our customers as per there requirement and projects. We have group of well trained engineers who are engaged in this activity and helps us in improving our product and consistency.